Everyone loves Kraut Space Magic, the Heckler & Koch G11 in particular so may recently have seen some photos on social media of a pretty impressive Heckler & Koch G11K2 prop build.

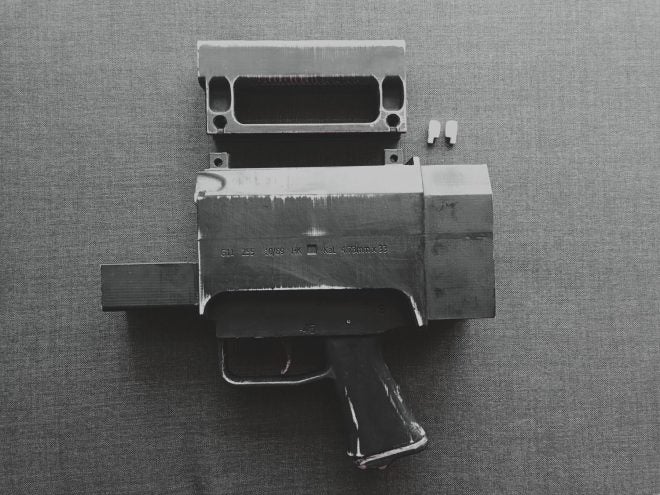

Impressive 3D printed G11K2 prop build (Nitrixflare)

HK were so impressed they even shared it on their Instagram page:

The 3D printed prop is so detailed that at a glance you might even be fooled into thinking HK let a G11 out of the Gray Room. We reached out to Nitrixflare, the builder behind the prop, to talk to him about tackling the iconic German rifle.

When and how did you start making prop guns? Have you always used 3D printing?

I started making props roughly 5 years back. I always wanted to be a small arms designer and I felt that building props gave me a little bit more exposure to various designs as a hobby. Typically, I have used 3D printing mainly due to ease in achieving complex parts. In the past when I had access occasionally I would use a mill or a lathe as well for some metal pins or whatnot for structural reasons. Nowadays it is typically the 3D printer, a cordless drill and a lot of handwork.

The freshly printed sections that make up the prop – shame HK never offered the two-tone pink & cream (Nitrixflare)

What made you want to recreate the HK G11? Was the G11 build challenging?

It’s funny because I always had a fascination for the “weirder” designs or those “rough around the edges”. I once joked I wanted to own all the prototypes in the G11 development cycle. The G11 for me was one of those props that was pretty much love at first sight and I knew I wanted one, just not sure when. So over my five years constructing I started hanging out with cosplayers who needed props. Over the past year or so a game called Girls’ Frontline gained traction, where guns were personified as individual characters. There were a few requests for the G11 so I thought, “Why not now?” The rest was history.

I would say the G11 is a funny one. On one hand it was easier to build considering its blocky exterior but on the other hand, it was challenging finding lots of high resolution reference pictures to look at considering it is quite a rarity.

A shot of the centre assembly and optic after an early coat of paint (Nitrixflare)

Is your G11 prop to scale? The detailed dimensions of the rifle aren’t easy to come by, did you have to put together your own CAD files?

Lengthwise, I would say yes. Width wise I had to exercise some creative thinking and calculations so probably not 100% accurate, but I’d say it’s close. Typically I’d research for the overall length, and then reverse engineer or calculate all the other dimensions. Yes, most of the time I draw up my own CAD files for props.

The prop even has the G11K2’s spare magazine holding slots either side of the loaded magazine (Nitrixflare)

This isn’t the first HK he’s tackled though, in the past he’s put together a UMP and a 417:

Nitrixflare’s UMP9 build (Nitrixflare)

Can you tell us a little about how 3D printing works, was it difficult to recreate the G11?

Well, there are different forms of 3D printing, but the one I mainly use is FDM or filament deposition modelling. A spool of plastic filament is melted and built up over layers to form the finished part. I’d say the biggest challenge in constructing the G11 was its bulk, and it consumed a relatively large amount of material on the machine. Due to the large parts, print times were long too.

Nitrixflare even made an optic for the prop complete with reticle (Nitrixflare)

You even printed some of the G11’s caseless ammunition?

I attempted to, I thought it would be a nice complement to the prop. At this juncture, I have yet to succeed as the ammunition was surprisingly small, not something that the machine would be good at printing. You look at pictures without scale thinking the rounds are decent in size but then you’re reminded the overall ammunition length was only slightly over 30 millimeters.

Once the pieces are printed how do you go about actually making the gun look realistic?

So the thing about 3D printed parts is due to the layering process you can see lines on the parts. Typically I would fill out these lines and proceed to do a lot of sanding to get surfaces flat. Then I try to find suitable paints to match the original photographs as closely as possible.

The completed build with recreations of the G11’s long single stack magazines (Nitrixflare)

Our thanks to Nitrixflare for talking to us about his build, you can check out more photos of the Nitrixflare’s G11 build and his other work here.

Nitrix tells us that after the G11K2 he has a whole list of project to work through, including some Russian space magic – the AN94, the AEK-999 and OTS14 and following that a classic, the FN FAL.